|

ABOUT

|

TECH INFO

|

Q&A

|

CATALOG

|

SHIPPING

|

CONTACT

|

HOW to ORDER

|

CUSTOMERS COMMENTS |

|---|

|

|

|

#

Glassing in a scoop (general description) |

Install of SC204 on 1968 - 1974 Nova

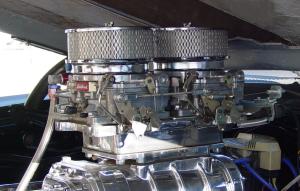

Cut hole in hood to clear intakes

|

'Glassing in a scoop All Unlimited's scoops are made thick enough along the sides so they will not fail when 'glassed' in. After determining the position and height needed, cut off base of scoop to desired height. Place scoop on hood in desired position and "trace" scoop base on hood. Using a 'diamond' edged saw (standard jig saw will

work), cut a hole into the hood along the "trace". This should match the

base of the scoop. |

Place scoop

on hood and flip assembly over. Place scoop

on hood and flip assembly over.Using fiberglass matting and cloth, glass scoop into hood. Being careful to lay-up enough glass to firmly attach sccop to to hood. To finish, hand sand top to a professional look. Now you have great installation that will not fail

at the bond line! |

|

Fiberglass scoop to fiberglass hood Use proper masks and eye protection when working with fiberglass!

When using resin and fiberglass to install fiberglass scoops to fiberglass hoods, use ½ the normal amount to catalyst to avoid resin over heating and causing distortion to your final work. Excessive heat during the cure will cause distortion to the hoods flat areas and make for al of extra finishing work. . |

|

Scoop installation procedure Fiberglass scoop to steel hood Use proper masks and eye protection when working with fiberglass! 1. Place scoop on hood in desired position. To determine best position it is best done with hood on car. Measure height of scoop. If scoop is too tall then cut base of scoop to desired size. hen cutting base - contour it to hood shape. 2. Place scoop back on hood in desired position, draw outline of scoop onto hood. Rough the steel hood with sand paper (down to bare metal) in the areas that the scoop will be attached. 3. Then drill various pop rivet holes through the scoop and the steel hood (approx. 3 inches apart), being careful that the scoop does not move from the desired position. Use flat head type pop rivets and countersink the holes slightly so the rivets can be left in place. 4. Apply fiberglass matting and fiberglass resin along the attachment areas, pop rivet down while the resin is we. Let harden. 5. Grind to flare in the edges of the scoop to the hood surface, apply body filler and smooth out. 6. You can now sand the entire hood and scoop surface in preparation for paint .

|

|

For scoops that have internal flanges:

1. Mark off holes in 10 or more places as needed and drill with ¼" drill bit.

2. Install ¼" bolt washer and T-nut. 3. Apply body filler around T-nut to hold in place. 4. When body filler has set up,

remove ¼" bolt.

Included with bolt sets (bolt sets are

not included

with all scoops that have internal flanges): UP22.com the web's giant-giant site for quality fiberglass. Customers agree, fit, price, quality all come together at UP22.com. Please visit UP22.com frequently to see updates, specials and new items. Or visit our factory in Hesperia CA. You can pick up items (call ahead) or just browse our huge factory. You can request to see our lay-up shop and see how our products are made!

|